In today’s modern world, structures like skyscrapers, and hi-tech vehicles need such materials that consist of suitable properties that fulfill the functionality of that particular product. No one material is perfect and has all properties. Some material has good hardness but poor ductility. Some have good thermal conductivity but poor strength. Some have good toughness but poor formability. To get the suitable properties, a process called “Heat treatment” is used.

What is the Heat treatment process?

The various stages of heat treatment process are…

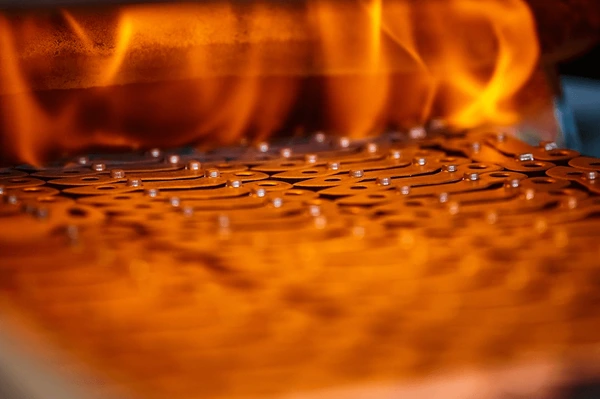

Heating – Heating the material uniformly. Non-uniform heating causes the formation of non-uniform microstructure resulting in cracks on a surface.

Soaking – Holding the material at a specific temperature for a certain period to achieve desired properties.

Cooling – Cooling the material at a suitable rate. The cooling of material is

done rapidly, slowly, or quenched.

People also search – What is Strain hardening?

What is Annealing process?

During the cold working process, Annealing is performed to increase the formability of the material. Annealing is a heat treatment process that modifies the crystal structure of the material and improves its ductility by relieving the residual stresses induced by the previous process.

In the annealing process, the material is heated uniformly at a suitable temperature. Due to heat, the microstructure of the material starts to modify. When a suitable temperature is achieved, the material is held at that temperature. This is called socking. The holding time varies from seconds to 60 hours. During socking, the grain boundaries of microstructures are broken and the formation of new crystal structures takes place. After the formation of a new crystal structure, the material cools slowly.

There are a few types of annealing processes listed below.

Full Annealing – Generally Full annealing is performed on low and medium carbon steel (ferrous metals). During Full annealing, the material is heated in the austenite region and produces course pearlite by slowly cooling in the furnace.

Process Annealing – Cold-worked parts are frequently annealed to improve ductility and minimize the effect of strain hardening. This heat treatment process lets the strain-hardened parts recrystallize completely or partially. Recrystallization depends on heating temperature, socking time periods, and cooling rates. To increase the formability of the material, an annealing process is carried out in between the cold working process which is known as Process Annealing which allows the further cold working of part.

What is Normalizing process?

Normalizing is a similar heat treatment process to annealing having heating, socking, and cooling cycles. The only difference is the cooling rate.

Normalizing processes can be performed on alloys like Brass, Nickel-based alloys, Aluminium, Copper, and Iron-based alloys.

What is the difference between annealing and normalizing heat treatment?

The major difference between the annealing and normalizing heat treatment process is the “Cooling rate of material”

In Annealing, the material has a slow cooling rate as the material is cooled down in the furnace by a controlled cooling rate. While in Normalizing, the material is cooled down at atmosphere room temperature having a faster cooling rate compared to annealing.

Due to the slow cooling rate in the annealing process, the ductility of the material is good compared to Normalizing. In Normalizing, due to the faster cooling rate, the formation of fine pearlite takes place, resulting in high hardness but lower ductility than annealing.