What Is Meshing – Ansys Physics Preference

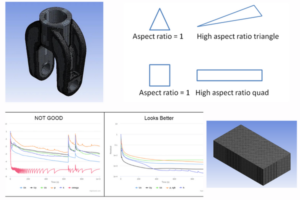

The first step is to analyze any object in ANSYS is create proper meshing of that object which is to be analyzed. The result of the analysis completely depends on the quality of meshing. So, “what is meshing ?”

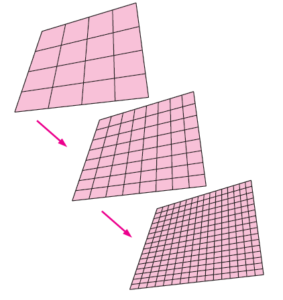

Meshing is the discretization of the continuous body into a finite number of elements. Meshing is defined as the process of dividing the whole component or part or body into a number of elements so that whenever the load is applied on the component it distributes the uniformly called meshing.

After Meshing, the entire body or part is divided into a small number of elements, and each element has its own stiffness while loading. Adding all those elements stiffnesses, you can get the Global Stiffness Matrix with which you can calculate the stress developed in the structure, etc.

people also search MESH GENERATION AND CFD STEPS

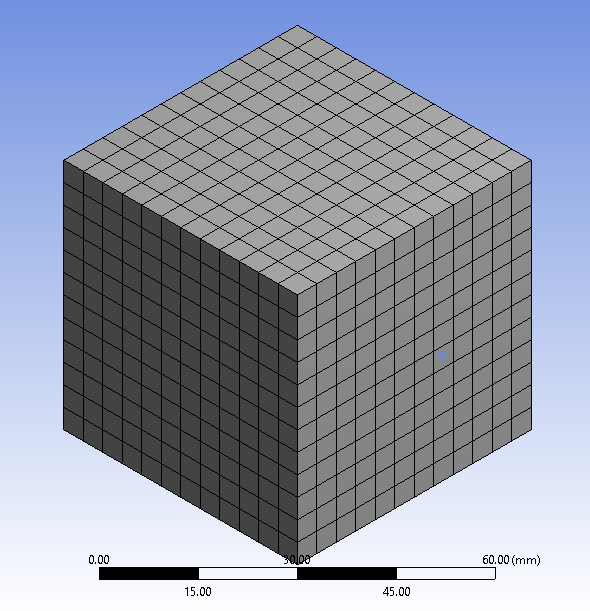

Generally, No one meshing is perfect. The type of meshing is depended on your project or object. If you are doing solidity or durability analysis then at critical regions, more finer mesh with more no. of elements should be placed and you can’t use tetrahedral mesh because it is unstructured mesh which is not much finer than structured mesh.

Here is some basic guideline to use quadrilateral/hexahedral meshes.

• For moderately complex geometries, use unstructured quadrilateral/hexahedral meshes.

• For relatively complex geometries, use triangular/tetrahedral meshes with wedge elements in the boundary layers.

• For extremely complex geometries, use pure triangular/tetrahedral meshes

- If you are still now confused about selecting mesh type for your object, You can try multi-griding (mesh) method. First Use a larger element to mesh the profile and run the Analysis to obtain the results. Now you can decrease the size of elements and run analysis and see how much the difference between results obtained by larger mesh & smaller mesh.

- Choose the element size where you see the minimum changes in the results. This technique is also useful for reducing computational time. As the element size decreases, it increases the number of Nodes but also increases the accuracy of the result, but at the same time, it will take more CPU power.

There is various Ansys Physics Preference which is needed to choose before meshing :

Ansys Physics Preference

- Mechanical: The preferred meshers is used for mechanical analysis. It is patch conforming meshers (Patch Conforming Tetrahedrons and Sweeping) for solid bodies and any of the surface body meshers.

- Electromagnetics: The preferred meshers is use for electromagnetic analysis. It is also patch conforming meshers and/or the

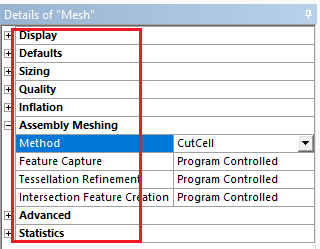

patch independent meshers (Patch Independent Tetrahedrons and MultiZone). - CFD: This meshers is used for CFD analysis. It is also patch conforming meshers and/or the patch independent meshers.

- Explicit Dynamics: This meshers is used for explicit dynamics on solid bodies. It is patch independent meshers. In ANSYS explicit dynamics we are capable of solving short-duration, large-strain, large-deformation, fracture, complete material failure, and structural problems with complex contact interactions.

- A Mesh is a small subset of the computational domain. For analyzing any object, First, a computational domain is chosen, and a mesh(also called a grid) is generated; the domain is divided into many small elements called cells. For two-dimensional (2-D) domains, the cells are areas, while for three-dimensional (3-D) domains the cells are volumes.

- You can think of each cell as a tiny control volume in which discretized versions of the conservation equations are solved. The quality of a CFD solution is highly dependent on the quality of the mesh. Therefore, It must be required to generation of the high-quality mesh before proceeding to the next step.

There are mainly two meshing methods available in ANSYS workbench to control the mesh of your object :

- Global Mesh Control

- Local Mesh Control

Global Mesh Control

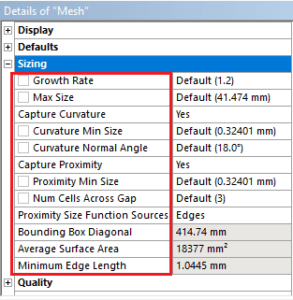

In global mesh control, You can control your mesh globally means whatever change you will, it will affect your whole object or body. There are many options available in global mesh control by which you can control your mesh on your object. For more information about global mesh control click here.

|

- Defaults Group

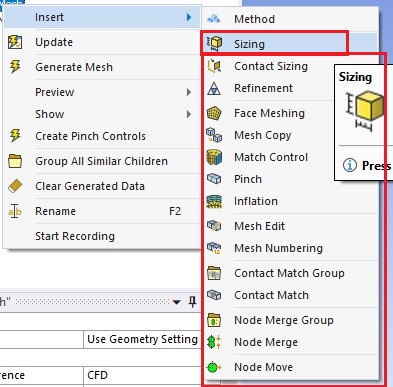

- Sizing Group

- Inflation Group

- CutCell Meshing Group

- Advanced Group

- Defeaturing Group

- Statistics Group

Local Mesh Control

In local mesh control, you can control your mesh locally means you can modify a mesh on a particular area in an object. The change in mesh does not affect on the whole object. There are many options available in local mesh control by which you can control your mesh on your object. For more information about local mesh control click here.

2 thoughts on “What Is Meshing – Ansys Physics Preference”